About Salt Boatworks

Hi, I’m Adam, the owner and designer at Salt Boatworks. I grew up fishing the Crystal Coast of North Carolina with my family and fell in love with the lines of the local work boats. Something so simple, yet so elegant, and unlike any mass produced boat available. I never lost my fondness for these boats and after graduation from NC State University in 2009 I decided to build a boat of my own.

Hi, I’m Adam, the owner and designer at Salt Boatworks. I grew up fishing the Crystal Coast of North Carolina with my family and fell in love with the lines of the local work boats. Something so simple, yet so elegant, and unlike any mass produced boat available. I never lost my fondness for these boats and after graduation from NC State University in 2009 I decided to build a boat of my own.

In 2012 I started looking for plans to build a Core Sound style skiff but none were available. So I reached out to many builders, designers, and Naval Architects that would mentor me over the next several years. I created the hull shape in CAD and started construction in 2013. Three very busy years later the boat was completed. I then started designing jigs for some of my mentors, and in 2016 Salt Boatworks became an official company. I have been doing boat design for various companies since.

I offer stock and custom boat designs so you can experience the enjoyable and rewarding journey of building your own boat.

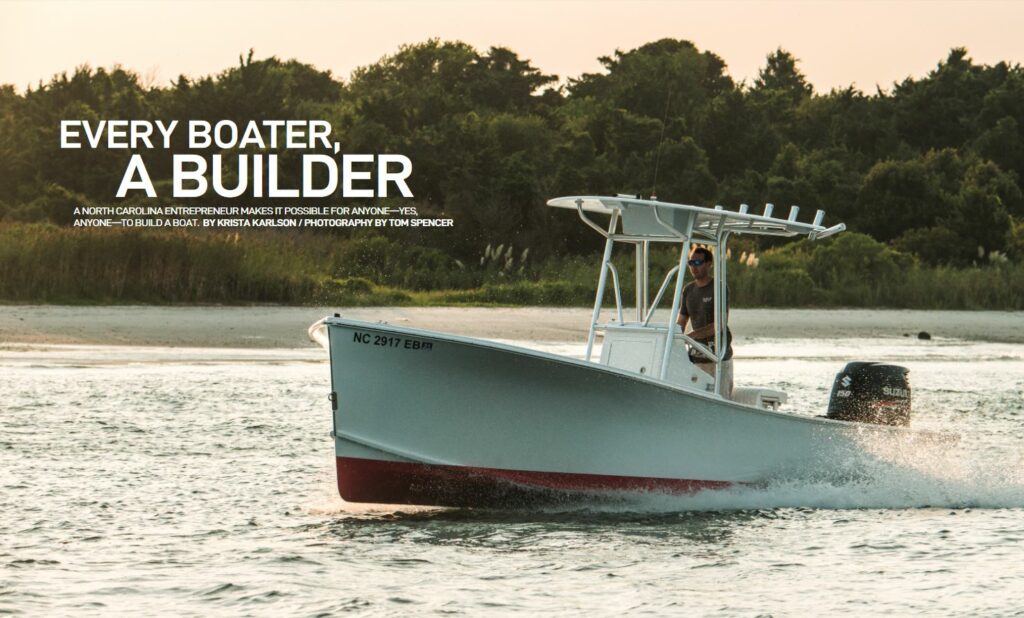

EVERY BOATER, A BUILDER

Published in Outboard Magazine Spring 2019 and and Power & Motoryacht Magazine June 2019.

Story by Krista Karlson. Photography By Tom Spencer.

The 1950s table saw in Adam Parchman’s garage is stored neatly beside a workbench covered with boatbuilding plans. It has no safety features to speak of. When I approach the saw with wood in hand, Parchman politely tells me he’ll do the cutting.

Parchman has been using this saw since he was a kid, when he built a barn with his grandfather out-side Goldsboro, North Carolina. His grandfather, a carpenter and a farmer, taught him to measure, hammer and saw while his parents were away for the weekend. “I [had] a blast,” he says, with a wide smile perched atop his gangly frame.

When he was a kid, he didn’t get in trouble for failing to clean his room or eat his vegetables. He got in trouble for taking things apart. “I was the kid who took stuff apart to try to figure out how it worked, and then put it back together,” says the engineer, now 32. As he grew, so did his curiosity.

Parchman is talkative and endearing. He speaks with the precision of an engineer and the sentimentality of a craftsman. He founded Salt Boat-works in 2016, a company that sells boatbuilding plans and jigs to anyone who wants to build a boat, but he’s been designing and selling boats for decades. In high school, he fixed up aluminum jon boats and sold them in the classifieds. “Before I could drive, my mom was driving me around and I was like, ‘Stop at this house. There’s an old boat in the backyard. I gotta go see if they’ll sell it to me,’” he recalls.

His fascination with boats stayed with him through college, when he noticed a 60-foot boat being built in a barn not far from the campus of North Carolina State University. The builder was a recent graduate, and the two became friends. Around that time Parch-man realized, “This is what I want to do with my life.” He scoured boat shows asking every builder if he could talk to the manufacturing team, hoping he might get lucky and land an internship. “I [was] a college kid with this really bad resume,” he told me recently dur-ing a visit to his North Carolina home. That was 2008, and everyone he spoke with said it was a bad time to go into the boat business.

As we drive toward Bogue, where Parchman lives, he points out overturned picnic tables and trees snapped in half by Hurricane Florence, which devastated the area just months before my visit. There’s still debris on the highway, and we pass a church with a flooded yard. Parchman and his wife, Emily, stayed put during the storm. “I’ll buy a generator and carry some insurance,” he says, in exchange for living in what he considers to be paradise most of the year.

We turn onto a quiet cul-de-sac where most households have a boat either in the driveway or tied up at the neighborhood slip. The first boat that Parchman designed and built from scratch is in a slip visible from his home.

After college, Parchman’s industrial design degree landed him a job at a truck body company. “It was a good job, but it was not boats and it was not in Eastern North Carolina,” he says. On his lunch breaks, he sketched boats. He worried that when the market rebounded, he’d be the guy with a college degree but no experience in the industry. He decided to gain experience by building his own boat, so he called and visited dozens of mentors including Donnie Caison of Caison Yachts and Shay Trainer of Trainer Boatworks, who provided generous guidance. He remembers many of them saying, “You’re a crazy young kid. I like you.”

Parchman designed his first boat—a 21-foot center console—using CAD, a skill he’d learned in college. His mentors taught him about cold molding, making a jig and using a CNC machine. “I’m the one building the boat, but all these people are pouring all this time and knowledge and skills into me. They always have the door open for me,” he remembers thinking. “This community is something that doesn’t happen in the corporate world where I work during the day.”

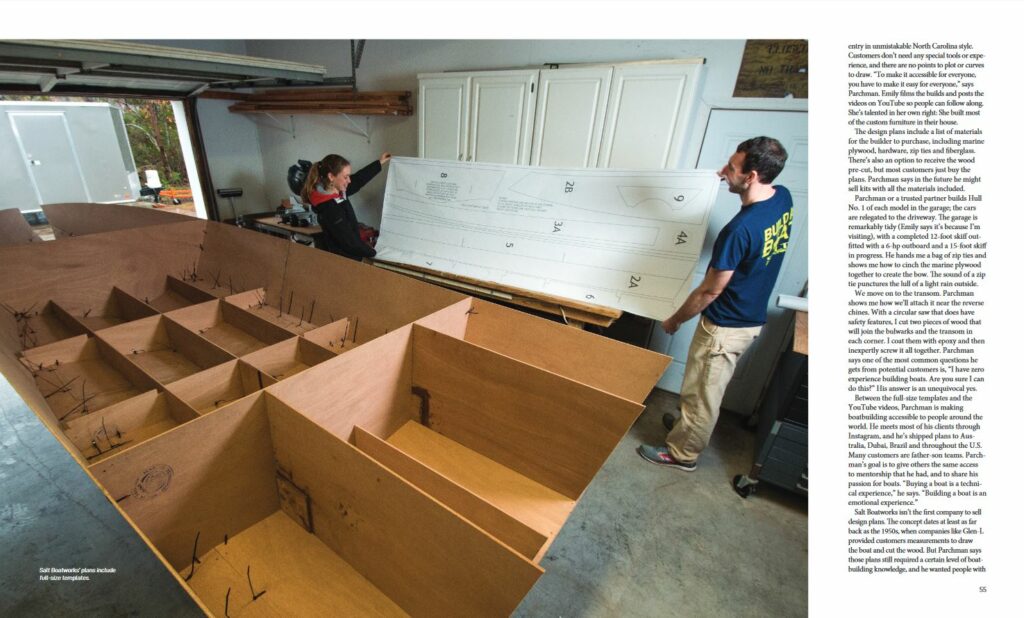

It took him two and a half years to build that first boat, named Learning Curve, a center console outfitted with a 150-hp Suzuki. When he shared his work on social media, people expressed interest in building their own. In 2016, he responded to this demand by founding Salt Boatworks. Customers can purchase plans with full-size templates for a 12- or 15-foot skiff or an 18- or 21-foot center console, each with a flared bow and sharp entry in unmistakable North Carolina style. Customers don’t need any special tools or expe-rience, and there are no points to plot or curves to draw. “To make it accessible for everyone, you have to make it easy for everyone,” says Parchman. Emily films the builds and posts the videos on YouTube so people can follow along. She’s talented in her own right: She built most of the custom furniture in their house.

The design plans include a list of materials for the builder to purchase, including marine plywood, hardware, zip ties and fiberglass. There’s also an option to receive the wood pre-cut, but most customers just buy the plans. Parchman says in the future he might sell kits with all the materials included.

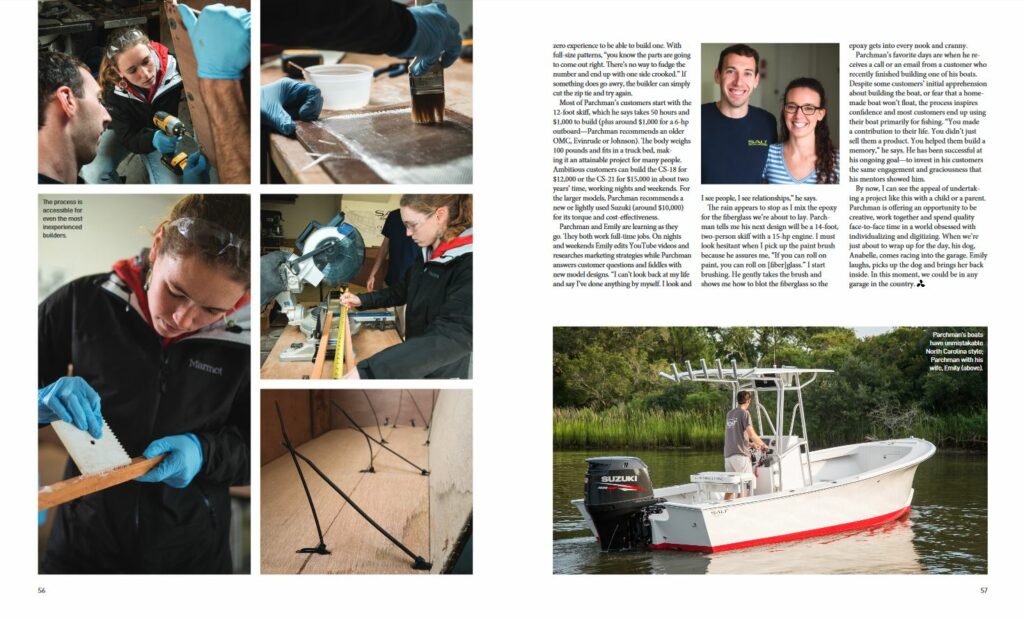

Parchman or a trusted partner builds Hull No. 1 of each model in the garage; the cars are relegated to the driveway. The garage is remarkably tidy (Emily says it’s because I’m visiting), with a completed 12-foot skiff out-fitted with a 6-hp outboard and a 15-foot skiff in progress. He hands me a bag of zip ties and shows me how to cinch the marine plywood together to create the bow. The sound of a zip tie punctures the lull of a light rain outside.

We move on to the transom. Parchman shows me how we’ll attach it near the reverse chines. With a circular saw that does have safety features, I cut two pieces of wood that will join the bulwarks and the transom in each corner. I coat them with epoxy and then inexpertly screw it all together. Parchman says one of the most common questions he gets from potential customers is, “I have zero experience building boats. Are you sure I can do this?” His answer is an unequivocal yes.

Between the full-size templates and the YouTube videos, Parchman is making boatbuilding accessible to people around the world. He meets most of his clients through Instagram, and he’s shipped plans to Australia, Dubai, Brazil and throughout the U.S. Many customers are father-son teams. Parch-man’s goal is to give others the same access to mentorship that he had, and to share his passion for boats. “Buying a boat is a technical experience,” he says. “Building a boat is an emotional experience.”

Salt Boatworks isn’t the first company to sell design plans. The concept dates at least as far back as the 1950s, when companies like Glen-L provided customers measurements to draw the boat and cut the wood. But Parchman says those plans still required a certain level of boat-building knowledge, and he wanted people with zero experience to be able to build one. With full-size patterns, “you know the parts are going to come out right. There’s no way to fudge the number and end up with one side crooked.” If something does go awry, the builder can simply cut the zip tie and try again.

Most of Parchman’s customers start with the 12-foot skiff, which he says takes 50 hours and $1,000 to build (plus around $1,000 for a 6-hp outboard—Parchman recommends an older OMC, Evinrude or Johnson). The body weighs 100 pounds and fits in a truck bed, mak-ing it an attainable project for many people. Ambitious customers can build the CS-18 for $12,000 or the CS-21 for $15,000 in about two years’ time, working nights and weekends. For the larger models, Parchman recommends a new or lightly used Suzuki (around $10,000) for its torque and cost-effectiveness.

Parchman and Emily are learning as they go. They both work full-time jobs. On nights and weekends Emily edits YouTube videos and researches marketing strategies while Parchman answers customer questions and fiddles with new model designs. “I can’t look back at my life and say I’ve done anything by myself. I look and I see people, I see relationships,” he says.

The rain appears to stop as I mix the epoxy for the fiberglass we’re about to lay. Parchman tells me his next design will be a 14-foot, two-person skiff with a 15-hp engine. I must look hesitant when I pick up the paint brush because he assures me, “If you can roll on paint, you can roll on [fiber]glass.” I start brushing. He gently takes the brush and shows me how to blot the fiberglass so the epoxy gets into every nook and cranny.

Parchman’s favorite days are when he receives a call or an email from a customer who recently finished building one of his boats. Despite some customers’ initial apprehension about building the boat, or fear that a home-made boat won’t float, the process inspires confidence and most customers end up using their boat primarily for fishing. “You made a contribution to their life. You didn’t just sell them a product. You helped them build a memory,” he says. He has been successful at his ongoing goal—to invest in his customers the same engagement and graciousness that his mentors showed him.

By now, I can see the appeal of undertaking a project like this with a child or a parent. Parchman is offering an opportunity to be creative, work together and spend quality face-to-face time in a world obsessed with individualizing and digitizing. When we’re just about to wrap up for the day, his dog, Anabelle, comes racing into the garage. Emily laughs, picks up the dog and brings her back inside. In this moment, we could be in any garage in the country.